Concrete - Workability - Compacting Factor

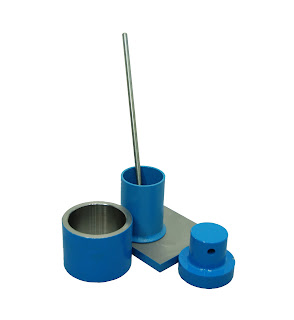

AIM To determine the workability of fresh concrete by compacting factor test as per IS: 1199 - 1959. APPARATUS COMPACTING FACTOR APPARATUS Compacting factor apparatus PROCEDURE The sample of concrete is placed in the upper hopper upto the brim. The trap-door is opened so that the concrete falls into the lower hopper. The trap-door of the lower hopper is opened and the concrete is allowed to fall into the cylinder he excess concrete remaining above the top level of the cylinder is then cut off with the help of plane blades. The concrete in the cylinder is weighed. This is known as weight of partially compacted concrete. The cylinder is filled with a fresh sample of concrete and vibrated to obtain full compaction. The concrete in the cylinder is weighed again. This weight is known as the weight of fully compacted concrete. REPORTING OF RESULTS Compacting factor = (Weight of partially compacted concrete/ Weight of...