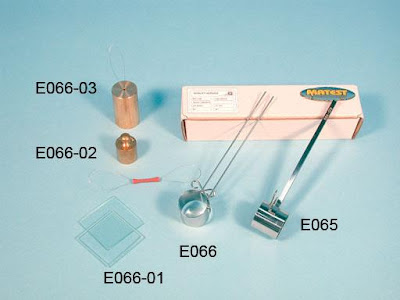

AIM To determine the fineness of cement by dry sieving as per IS: 4031 (Part 1) - 1996. PRINCIPLE The fineness of cement is measured by sieving it through a standard sieve. The proportion of cement, the grain sizes of which, is larger than the specified mesh size is thus determined. APPARATUS IS SIEVE Balance capable of weighing 10g to the nearest 10mg 90μm IS Sieve A nylon or pure bristle brush, preferably with 25 to 40mm bristle, for cleaning the sieve PROCEDURE Weigh approximately 10g of cement to the nearest 0.01g and place it on the sieve. Agitate the sieve by swirling, planetary and linear movements, until no more fine material passes through it. Weigh the residue and express its mass as a percentage R1, of the quantity first placed on the sieve to the nearest 0.1 percent. Gently brush all the fine material off the base of the sieve. Repeat the whole procedure using a fresh 10g sample to obtain R2. Then calculate R a...